AlTi alloy Sputtering Target High Purity

Aluminium Titanium

Qhov kev xav tau ntawm lub hom phiaj zoo rau sputter txheej yog siab dua li ntawm cov khoom siv niaj hnub kev lag luam.Cov qauv microstructure ntawm lub hom phiaj ncaj qha cuam tshuam rau kev ua haujlwm ntawm sputtering.Peb muaj kev tswj hwm kev ua tiav zoo thiab peb xaiv cov khoom siv purity siab thiab ua kom zoo sib xyaw kom ntseeg tau homogeneity.Aluminium Titanium alloy sputtering lub hom phiaj yog tsim los ntawm lub tshuab nqus tsev kub nias txoj kev.

Peb lub hom phiaj Aluminium Titanium sputtering tuaj yeem muab qhov zoo tshaj plaws oxidation-resistant nitride txheej, Titanium aluminium nitride (TiAlN).TiAlN yog lub ntsiab tam sim no ua yeeb yaj kiab rau cov cuab yeej txiav, zawv zawg qhov chaw thiab tribo-coatings.Nws muaj siab hardness, toughness, hnav resistant kev ua tau zoo thiab oxidation kub.

Peb cov hom phiaj AlTi thiab lawv cov khoom

| TSI-75Al ntawm% | TSI-70Al ntawm% | TSI-67Al ntawm% | Ti-60Al ntawm% | Ti-50Al ntawm% | Ti-30Al ntawm% | Ti-20Al ntawm% | Ti-14Al ntawm% | |

| Purity (%) | 99.7 ua | 99.7 ua | 99.7 ua | 99.7 ua | 99.8 /99.9 ua | 99.9 ua | 99.9 ua | 99.9 ua |

| Qhov ntom(g/cm3) | 3.1 | 3.2 | 3.3 | 3.4 | 3.63/3.85 Nws | 3.97 ib | 4.25 ib | 4.3 |

| Gnag Loj(µm) | 100 | 100 | 100 | 100 | 100/- | - | - | - |

| Txheej txheem | HIP | HIP | HIP | HIP | HIP/VAR | VAR | VAR | VAR |

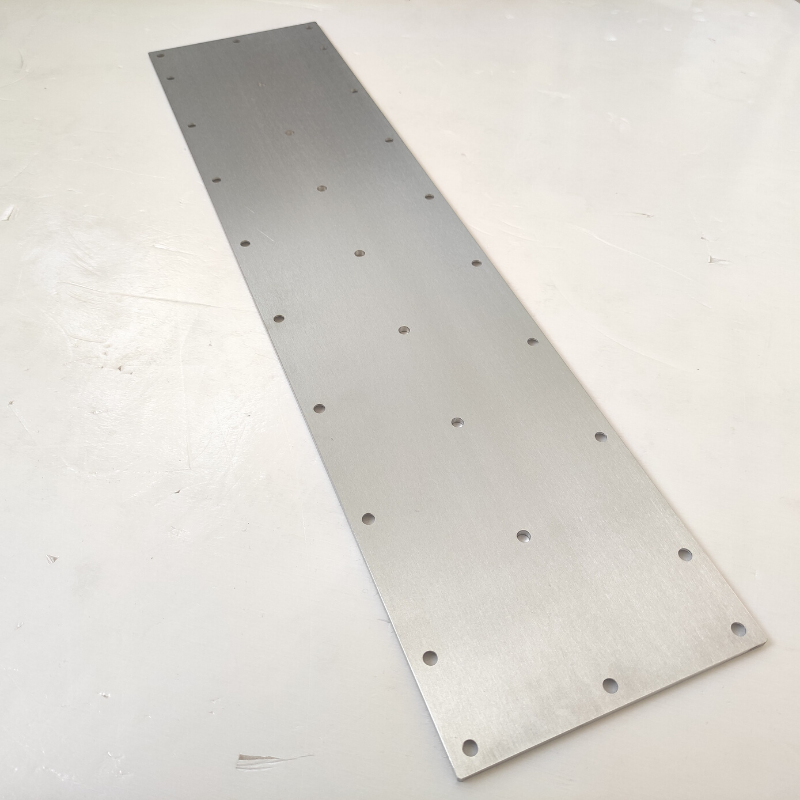

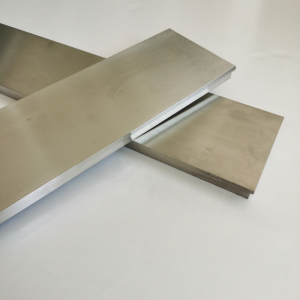

Cov Khoom Muag Khoom Tshwj Xeeb Tshwj Xeeb tshwj xeeb hauv Kev Tsim Cov Txheej Txheem Sputtering thiab tuaj yeem tsim Aluminium Titanium Sputtering Materials raws li cov neeg siv khoom tshwj xeeb.Peb tuaj yeem muab ntau hom duab geometric: raj, arc cathodes, planar lossis custom-made, thiab dav feem ntau ntawm Aluminium.Peb cov khoom muaj cov khoom siv zoo heev, homogeneous microstructure, polished nto tsis muaj kev sib cais, pores lossis tawg.Yog xav paub ntxiv, thov hu rau peb.