Ua ntej, ntau tus neeg siv khoom nug cov npoj yaig los ntawm RSM Technology Department txog titanium alloy.Tam sim no, kuv xav sau cov ntsiab lus hauv qab no rau koj txog dab tsi hlau titanium alloy yog ua los ntawm.Kuv vam tias lawv yuav pab tau koj.

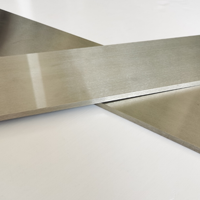

Titanium alloy yog ib qho alloy ua los ntawm titanium thiab lwm yam khoom.

Titanium yog homogeneous heterogeneous siv lead ua, nrog lub melting point ntawm 1720 ℃.Thaum qhov kub thiab txias qis dua 882 ℃, nws muaj cov qauv zoo hexagonal lattice, uas yog hu ua α Titanium;Nws muaj lub cev nruab nrab ntawm lub cubic qauv saum toj no 882 ℃, uas yog hu ua β Titanium.Ua kom zoo dua ntawm cov yam ntxwv sib txawv ntawm ob lub qauv saum toj no ntawm titanium, cov ntsiab lus hlau tsim nyog tau ntxiv kom maj mam hloov nws cov theem hloov pauv kub thiab theem cov ntsiab lus kom tau txais titanium alloys nrog cov qauv sib txawv.Nyob rau hauv chav tsev kub, titanium alloys muaj peb hom matrix qauv, thiab titanium alloys kuj muab faib ua peb pawg hauv qab no: α Alloy (α + β) Alloy thiab β Alloy.Hauv Suav teb, nws tau qhia los ntawm TA, TC thiab TB feem.

α titanium alloy

Nws yog α Ib leeg-theem alloy tsim los ntawm theem khoom siv yog α Phase, ruaj khov qauv, siab hnav tsis kam tshaj titanium ntshiab, muaj zog oxidation tsis kam.Nyob rau hauv qhov kub ntawm 500 ℃ ~ 600 ℃, nws tseem tuav nws lub zog thiab creep tsis kam, tab sis tsis tuaj yeem ntxiv dag zog los ntawm kev kho cua sov, thiab nws lub zog kub hauv chav tsis siab.

β titanium alloy

Nws yog β Ib-theem hlau alloy tsim los ntawm theem khoom muaj zog ntau dua yam tsis muaj kev kho cua sov.Tom qab quenching thiab aging, lub alloy yog ntxiv dag zog, thiab chav tsev kub lub zog yuav ncav cuag 1372 ~ 1666 MPa;Txawm li cas los xij, lub thermal stability tsis zoo thiab nws tsis haum rau kev siv ntawm qhov kub thiab txias.

α + β titanium alloy

Nws yog ob theem alloy nrog cov khoom zoo, kev ruaj ntseg zoo, zoo toughness, plasticity thiab high-temperature deformation zog.Nws tuaj yeem siv rau kev ua haujlwm kub siab, quenching thiab kev laus kom ntxiv dag zog rau cov hlau.Lub zog tom qab kev kho cua sov yog li 50% ~ 100% siab dua li tom qab annealing;Lub zog kub kub, tuaj yeem ua haujlwm ntawm 400 ℃ ~ 500 ℃ rau lub sijhawm ntev, thiab nws cov thermal stability tsawg dua α Titanium alloy.

Ntawm peb titanium alloys α Titanium alloys thiab α + β Titanium alloy;α Titanium alloy muaj qhov zoo tshaj plaws machinability, α + P Titanium alloy siv qhov chaw thib ob, β Titanium alloy tsis zoo.α Cov cai ntawm titanium alloy yog TA, β Code ntawm titanium alloy yog TB, α + β Code ntawm titanium alloy yog TC.

Titanium alloys tuaj yeem muab faib ua cov khoom siv hluav taws xob tiv thaiv hluav taws xob, muaj zog alloys, corrosion resistant alloys (titanium molybdenum, titanium palladium alloys, thiab lwm yam), tsis kub-kub alloys thiab tshwj xeeb ua haujlwm alloys (titanium hlau hydrogen cia cov ntaub ntawv thiab titanium nickel nco alloys. ) raws li lawv daim ntawv thov.

Kev kho cua sov: titanium alloy tuaj yeem tau txais cov theem sib txawv thiab cov qauv los ntawm kev kho cov txheej txheem kho cua sov.Nws yog feem ntau ntseeg tias zoo equiaxed microstructure muaj zoo plasticity, thermal stability thiab qaug zog;Cov qauv acicular muaj zog rupture siab, creep zog thiab puas toughness;Mixed equiaxed thiab acicular cov ntaub so ntswg muaj kev ua haujlwm zoo dua

Post lub sij hawm: Oct-26-2022